capabilities

quality and precision - every step of the way

Material handling

quality materials

High-quality steel structures begin with top-notch materials. We collaborate with trusted suppliers to ensure that all our steel meets or exceeds contract documents and client-supplied shop drawings, guaranteeing exceptional results. By sourcing premium materials, we produce durable, visually stunning structures that surpass expectations and stand the test of time.

Programming

material sourcing

- Autonomous steel transport

- Material handling

- Quality Control

- Traceability

Material Handling

PROGRAMMING

STREAMLINED 3D WORKFLOW

Our software seamlessly generates files and integrates them into our machinery for streamlined steel fabrication. Skilled programmers review and align the files with your detailing, ensuring smooth integration. With programming experts and cutting-edge software, you can confidently trust in our unmatched precision, efficiency, and performance.

Thermal Cutting

programming Capabilities

- Detailing file integration (.DXF, .NC1, .XML3d, etc)

- Advanced software technology

- Flexible workflow meets unique requirements

Programming

robotic thermal cutting

Peddibot - 1200

We utilize the Peddinghaus PeddiBot-1200 thermal cutting machine to cut steel with precision and accuracy. This advanced machine reduces labor costs and increases production capacity, ensuring that each piece of steel is cut to meet the required specifications.

Shot Blasting

360°

part coverage

8

axis technology

Thermal Cutting Capabilities

- Bevels, miters, and flanges

- High-precision and accuracy

- Custom shapes & designs

Thermal Cutting

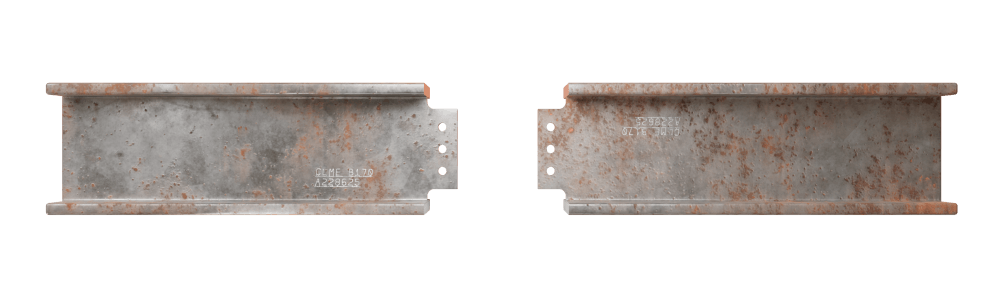

Shot blasting

Peddinghaus PeddiBlast

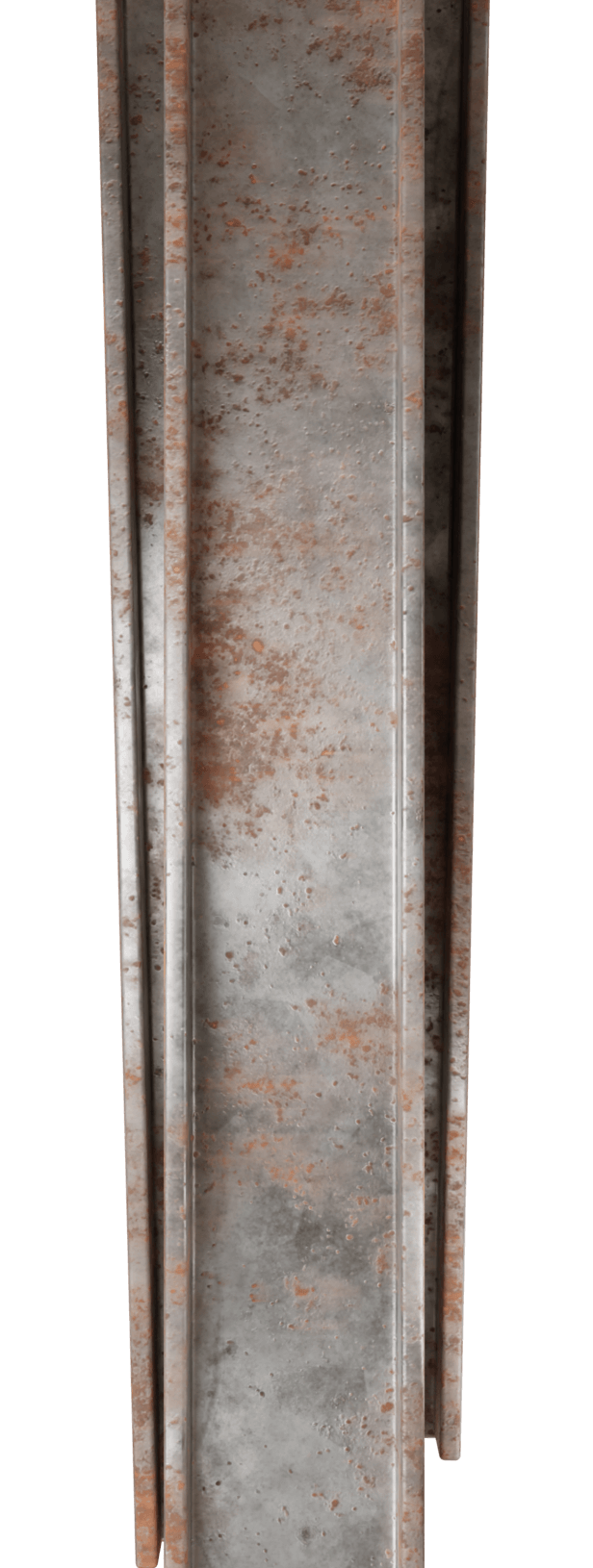

The Peddinghaus PeddiBlast is a shot blasting machine that removes rust and other contaminants from steel, creating a clean and finished surface that is ideal for painting, powder coating, or galvanizing. This machine provides a consistent finish, ensuring that each piece of steel meets our high-quality standards.

Robotic Fabrication

20HP

turbine power

4

turbine count

shot blasting capabilities

- Uniform blast pattern

- Adjustable blasting intensity

- Abrasive blasting

Shot Blasting

robotic & manual fabrication

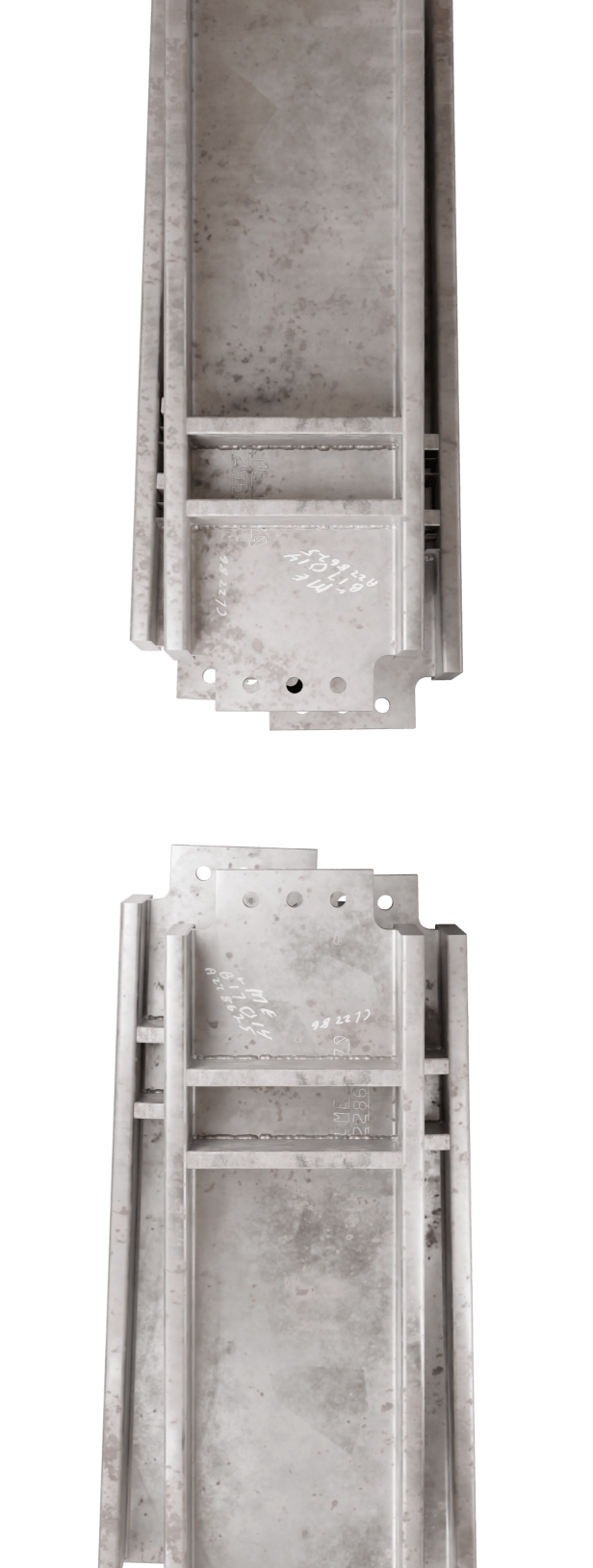

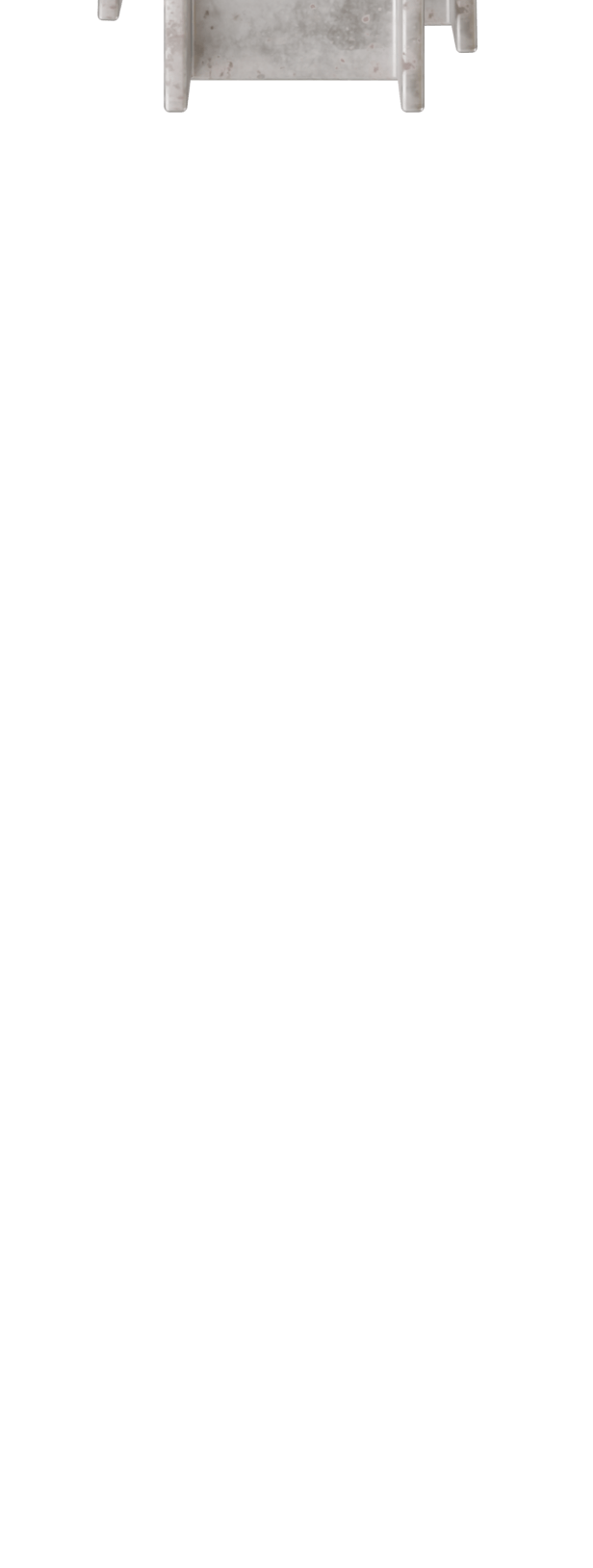

Zeman SBA Compact+ 1100

Our Zeman SBA Compact+ 1100 robotic welding and fabrication system revolutionizes the steel industry. With its advanced capabilities, we produce steel structures quickly and accurately, reducing lead times and increasing production capacity. This allows us to consistently deliver exceptional results to our clients, providing the flexibility to customize our solutions based on the specific needs of your project.

Quality Control

44.3in

maximum width

60ft

maximum length

fabrication Capabilities

- Laser scanning & 3d modelling

- Advanced quality control technology

- Custom shapes & designs

- Skilled welders and fabricators

Robotic Fabrication

quality control

thorough and consistent

We perform a comprehensive inspection of each steel component to ensure that it meets the required specifications and that the final product is safe and reliable. If any issues are identified, the team at Axis takes immediate corrective action to ensure that the final product meets the highest standards of quality and safety.

Contact Us

quality checks

- Cutting and Machining Inspection

- Surface Finish Inspection

- Assembly Inspection

- Welding Inspection

- Non-Destructive Testing